57rustbucket.com

Bed and wheel well replacement

4/5/18

|

|

This is what I'm facing next

|

|

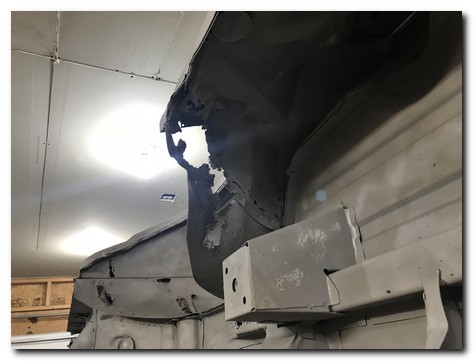

Terrible rot throughout the entire structure

|

|

There is very little left of the bed supports, the bed and the rear quarter fillers.

|

|

|

This is what will replace that old rotted bed. It's a very impressive piece. Along with it both wheel wells and quarter fillers will be replaced with new parts.

|

|

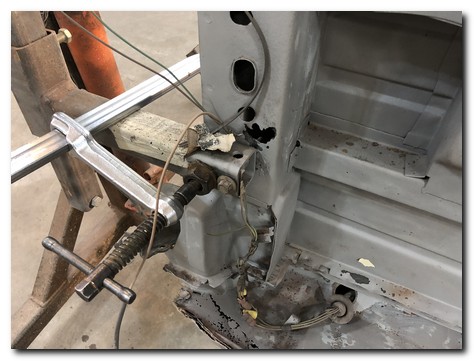

I'm going to be removing nearly all of the structural integrity of the back half of the car. I built a support structure of 1x1 square steel tubing. This will hold everything in perfect alignment while I'm working on it.

|

|

I rolled her upside down and used two large oil cans and two jack stands to support the rear area in exactly the correct position.

|

|

After verifying everything was level front to rear I removed the rotisserie from the back of the body.

|

|

Using a reciprocating saw I spent forever cutting around the perimeter of the bed.

|

With a little help of the engine hoist I

lifted it free like a can opener.

|

I now need to drill 12 billion spotwelds around the area highlighted to remove the remnants of the bed.

|

|

Just a whole lot of drilling and breaking free of some very old metal.

|

|

|

|

And just continued to drill around the wheel well and into the rear area.

|

A look at the passenger side, a lot of work left to be done.

|

Once the rear main support is removed it's clear why the support structure we bult is needed to keep it all together.

|

Finally the driver side filler is pulled free.

|

|

The wheel wells are spotwelded in dozens of areas. It clearly needs to be replaced.

|

|

The picture on the left is looking straight down into the bed side. There is a support that is welded to the top lip of the wheelhouse. I wont be able to reattach this without removing the bedside. The bedsides will be replaced at a later date. Finally the drivers wheel well comes free.

|

|

Just a rusted mess. I will need to fabricate some patches for the inner bed side and then can proceed with beginning to fit the new parts.

|

|

After patching, test fitting the well and filler panel. Starting to look good!

|

Big jump between pictures. It's all plug welded together with a protective layer of paint. The new parts fit really well after a few modifications.

|

|

|

A very ugly mess of rust on the wheel well. Nothing we can't fix though.

|

|

Cutting out the rot is first on the list.

|

I worked this small piece of metal a long time to get the correct shape and making it fit. It curves in 3 different directions and has to dip back in for the bed to be flush with it.

|

|

Test fitting the new wheel well and filler panel.

|

|

Clamping everything in place and marking where holes need to be placed for the plug welding.

|

|

|

All solidly welded in, plug welds ground down and a protective layer of paint.

|

I again used the engine hoist to handle this huge heavy bed. It took a bit of prying, wiggling and forcing to get it into the correct position. It fit a lot better than I expected.

|

|

I took all the time it needed to verify it was back in the exact same position as the original. I had take a dozen different measurements of the original before I removed it. I was able to get the new bed exactly back to where the original was.

|

|

I had pre drilled the holes to plug weld on the sides and rear. I clamped everything in place and welded it all together constantly checking to make sure nothing moved.

|

|

Along the front edge I used several self tapping screws to hold it in place. It was a difficult area to get to while it was on it's back. Once I put the body back on the rotisserie...

|

|

...and rolled it on it's side it was much easier to weld that area. It's all brand new!

|

Looks great from the top as well. Fit like a factory part.

|

|

I began the job of scuffing every nook and cranny of the new parts to prepare for primer and bedliner.

|

|

I followed that with seam sealer on every place that two panels came together.

|

|

|

|

Getting closer, the perimeter is masked and I wiped down every inch with wax and grease remover.

|

|

Looks great! Two coats of black epoxy primer. It's incredible how making it all one color brings everything together.

|

|

Followed by black bedliner. It was a challenge to get into some of the areas under the bed.

|

|

Off with the masking and ready for another 50+ years.

Guess it's time to put everything back together now.

| Back to Page 7 | Home | Page 9 coming soon |

|

Other Projects

@ 57RUSTBUCKET.COM |

Page 1 2 3 4 5 6 7 9 |

Contact Us! |

||

3d Printer |

|