57rustbucket.com

Frame Repair

|

|

|

|

|

|

The lower portions of both front frame horns are riddled with rust, literally like Swiss cheese. I've never seen this on an A body frame before.

|

|

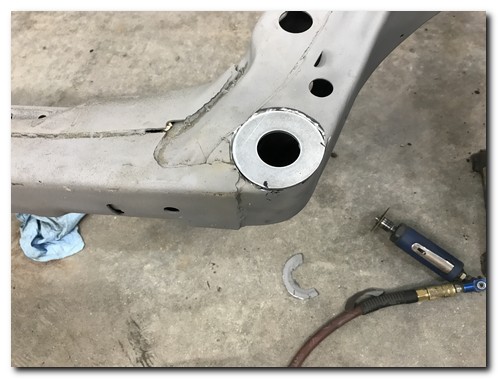

As expected there are a couple body mount holes that need rust repair. This is actually a simple repair that I've seen a lot of people turn into a big deal. First of all forget about buying the EXTREMELY overpriced repair washers from the well known restoration vendors. Go to your local hardware store and pick up a large washer with the proper inside diameter for less than a dollar.

|

|

Center it properly and run a marker around it. Cut that area out with a cutoff wheel.

|

|

Work the area slowly until the center is in the proper place. At this point grind the edge of the washer to fit the outside curve on the frame.

|

|

Weld in the washer and dress the weld with a grinder.

|

This is a simple very inexpensive repair to a common problem. It is visually seamless.

|

|

I then gave the frame several coats of black epoxy. Top and bottom being careful to get in all the cracks and crevices.

|

|

|

The remaining suspension components were also painted at the same time. Everything looks like new!

|

|

this is the passenger front frame horn bottom. I've found two very nice frame horns from a donor frame and will need to graft them to this frame. I spent quite a bit of time measuring and deciding what to remove and what to keep. I will be cutting to the outside of the masking tape.

|

|

Slowly cutting around the marked area.

|

|

The rusted area is removed leaving a good margin to ensure there is a solid foundation to weld the repair piece to.

|

|

Taking a lot of time I used the same measurements to mark off the donor horn. I cut it a little "fat" to leave a little wiggle room to work with.

|

|

The initial fit is very nice.

|

|

Working slowly with an angle grinder, I sneak up on the perfect fit to the hole in the frame.

|

|

I've recorded a bunch of measurements before cutting out the original piece and verify they agree with the new part.

|

|

Once I was confident it was correct I welded it in place.

|

|

After dressing the weld with a grinder and sander the seam disapears.

|

|

|

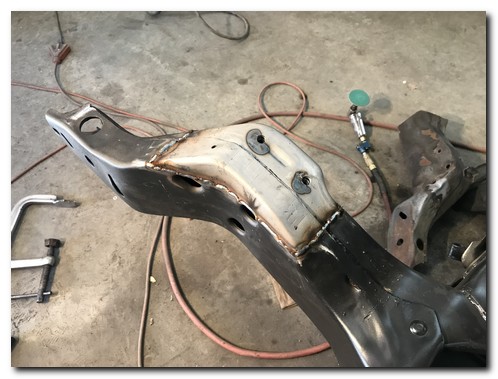

The drivers side is done the same way. The steering box is bolted to this area of the frame so the positioning must be much more exact.

|

|

The area cut out and the donor horn.

|

|

The needed area carefully cut from the donor horn as was done on the passenger side.

|

|

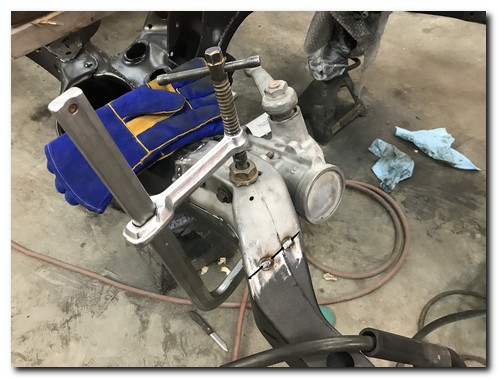

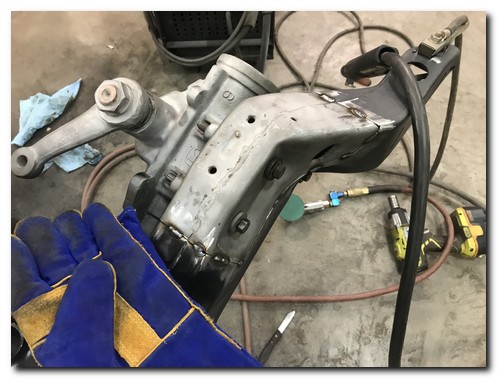

The fit is checked and "tuned in". I mounted the steering box to verify and maintain proper alignment.

|

|

Further checking and welding.

|

|

|

|

Getting it all cleaned up.

|

|

Like it never happened, both sides look terrific!

|

A final coat of epoxy.....

|

|

It looks as though it just came from the factory.

|

This repair was very satisfying. Taking something that looks like Swiss cheese and bringing it back to new is a lot of fun. |