1969 Olds Cutlass Convertible Restoration

Page 15

FOR SALE

|

|

|

I did a lot of final adjusting on the convertible

top frame. When it goes up it falls perfectly in place and latches

correctly.

I began with installing the bag the top folds

into.

Nearly everything about putting this top on is

finding the center of each component and matching it to the center of the car.

I measured carefully and used masking tape to mark the centers.

The rear edge was stapled to what's referred to as a floating bow.

It actually sits below the sheet metal at the rear.

.

|

|

I installed two 6x9 speakers in the rear and then contact cement was

used to secure the front of the bag.. |

Pads are placed on each side that go between the convertible top and the

frame.

They are stapled into new tack strips I installed in the bows. The

front is trimmed to fit the header bow.

Foam is inserted in the center and the two side flaps are folded over and

glued down.

|

|

The same thing was done on the passenger side. |

|

|

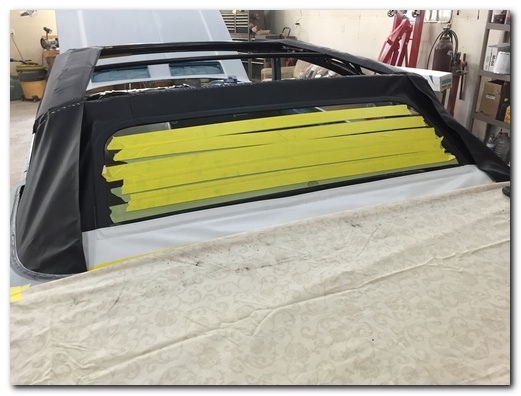

The rear curtain containing the rear window is once again centered and

then stapled to the rear floating bow and the rear bow at the top.

There are a lot of measurement that need to be made between the edge of

the rear lip and the rear top bow to get this tight and straight.

The tape on the back glass helps prevent any scratches. |

The top was set outside to warm in the sun and then placed over the frame.

After assuring it was centered a ton of measurements were made and

eventually it was stapled to the floating bow.

A lot of pulling stretching adjusting and stapling and she's got a new top.

Any minor wrinkles or draws should disappear once it sits in the sun for a

while.

I spent many hours cleaning the shop from top to bottom. The floor and

walls were scrubbed several times and anything I didn't need was removed

from the shop.

I began masking in preparation for paint.

After a thorough cleaning with wax and grease remover and wiping it down

with a tack rag 3 coats of slightly thinned epoxy primer was applied to seal

and provide a consistent base color for the paint.

Then three coats of base coat. WOW!

Three coats of clear and it shines like new!

After unmasking, getting the wheels back on and putting the top up.

She has come a long way.

Out in the sun she just shines!

While the paint cures I turned to a little less glamorous project. The

inner wheel wells and air dam need to be restored.

I'm really fortunate that the originals are in very good condition. No

cracks or ripped out mounting holes.

A good old soap and water cleaning and a little oven cleaner to remove some

undercoating and gunk on the underside. Looks pretty good.

Following all the proper procedures for painting plastic I applied a satin

black finish.

I used black shoe polish on the flaps. They look and fit much better

than the repros.

The air dam is also in terrific condition.

I removed the staples and like the inner fenders cleaned and painted the

plastic.

|

|

A thorough cleaning of the flap and new staples and I've got a "as new"

front air dam. |

After allowing the clear to dry completely it's time to knock the shine off

of it!

After sanding down some sags and runs in the clear I have begun wet sanding.

You can see the contrast between the door and front fender.

I'm using 800 grit sandpaper to remove any orange peel, dirt or any other

imperfections in the clear. That's followed with progressively finer

sand paper (1000, 1500, and 2000 grit) this will assure a near perfectly

flat surface. After buffing it should assure a mirror like finish.

A lot of work but it will look so much better.

Lots more to come!

Check back often.

Back

Back

Home

Home  Next

Next