1969 Olds Cutlass Convertible Restoration

Page 13

FOR SALE

|

|

|

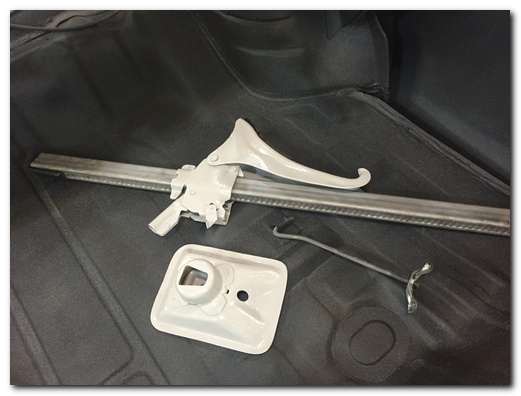

I began by finishing off the trunk. I first

primed it in black and then sprayed it with splatter paint. It looks as

good as the day it came off the assembly line. The shadows in the picture

really doesn't do it justice. It's a far cry from the rusted out mess I

started with.

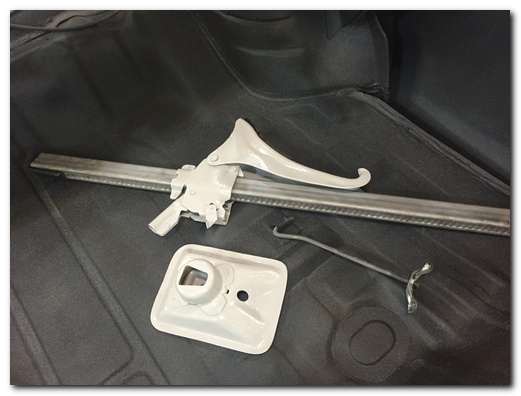

Bumper Jack

In keeping with the spirit of the trunk, I turned

to restoring a bumper jack. I salvaged this from a parts car.

It is from a 69 Cutlass and surprisingly was complete and still functioned.

It's pitted but overall in really good condition.

The picture on the left is of the jack base, the U69 indicates it's for

a 1969. On the right is from the saddle of the jack, again it indicates

it's for a 1968 or 69 . It's always kind of cool to find these types of

markings.

After sandblasting and a coat of gray, it looks really good. I

didn't do much with the pitting on the jack other than a bit of bodywork on

the bottom of the base where it is visible when the trunk is open.

|

|

All the parts except finished and reassembled.

I forgot to include the tire iron in this picture.

It hasn't looked this good for a few decades!. |

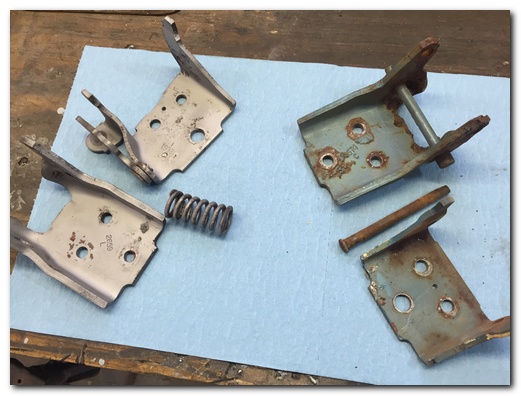

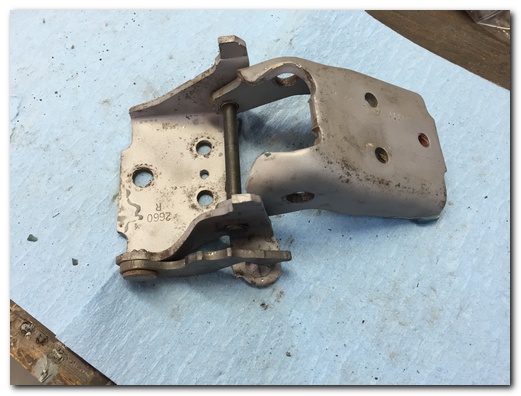

Door Hinges

I'm going to be mocking up body panels and doors on the body soon. I

need to rebuild the worn out door hinges first so everything is tight and

accurate. The bushings wear and get loose from years of supporting the

very large heavy doors.

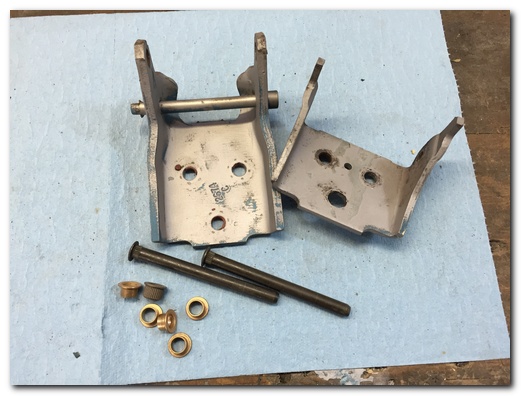

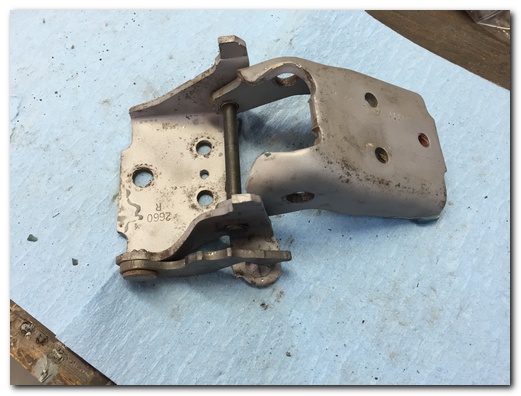

The pins, bushings and door check will be replaced.

First they are disassembled and sandblasted. Then the old bushings are

pushed out and new parts installed.

|

|

Once reassembled they are very tight and swing evenly. This

picture is before I had installed the door check and spring.

I also got ahead of myself a bit. I had planned on painting them

while they were apart. I'll still be able to mask them and paint

them later. |

Core Support

This is a HEAVY part!

The core support needed to be stripped down and restored next.

After lifting this monster up on a bench and finding a way to balance it

I can get to work on disassembly. |

|

|

Above on the left is the headlight "doors" or trim. It's all made of

plastic and has taken a real beating over the years. On the right is

the mount for it and located directly behind the trim. As you can see

it's in some pretty tough condition. Fortunately these are reproduced

and will be replaced with new parts.

Once again on the left is a pretty beat up mount for the trim. On the

right is the passenger side grill. As you can clearly see the bottom

is broken off. The bumpers would strike these and break them like this

one. The grills for the 442 Cutlass and an S Cutlass are different.

The 442 grills are reproduced but not the Cutlass S grills. I have

found a two nice repairable grills for replacement. They will need

minimal repair and then repainting to look new.

The core support stripped except for the horns and ready for the

sandblaster. The photo on the right is the lower air dam. I'm

very pleasantly surprised that it is in such great condition. It will

need a good clean up and maybe the plastic dyed black, but it's not cracked

or broken.

|

|

Core support has been sand blasted and ready for paint. It's so

nice to see fresh clean unrusted metal! |

These are the headlamp buckets and mounts. They mount to the core

support.

Pretty straightforward sandblast and repaint. I did need to replace

one adjusting spring but otherwise they are in great shape.

They turned out very nice and will look great for years to come.

Reinstallation of the core support was really a big step.

Installing the correct square mounts, running the wiring harness and

reconstructing the hood release linkage is really gratifying to get done.

The air conditioning condenser was put in place and then the plumbing for it

was run into the engine compartment as can be seen in the picture on the

left.

After the upper radiator support was sandblasted and painted it was

installed. Looks good!

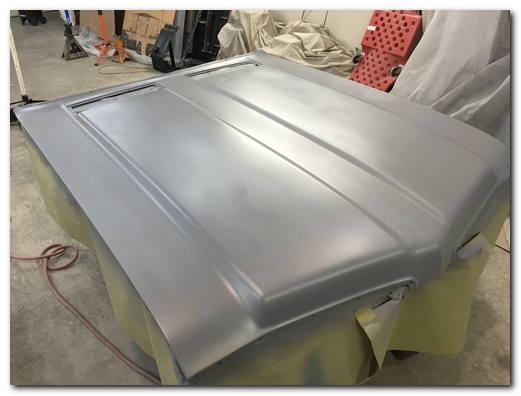

Hood and Deck Lid

Time to turn my attention back to the body.

The hood is just huge. It's been out in the elements for a very long

time. The brown is actually the original primer from the factory.

It appears to be very solid and straight, but I've been fooled before.

So we'll see.

|

|

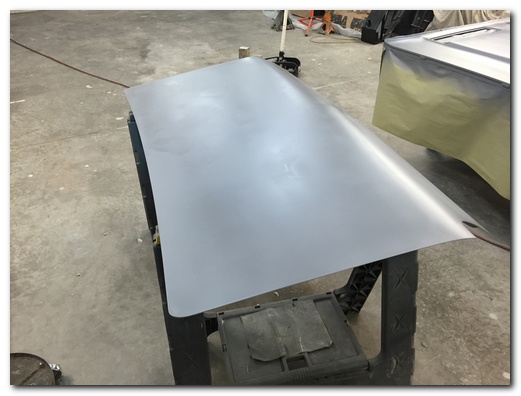

I started with the bottom.

Nothing real exciting, just a lot of sanding and elbow grease to prepare

it for paint.

Then a few nice coats of semi gloss black and it is ready for action. |

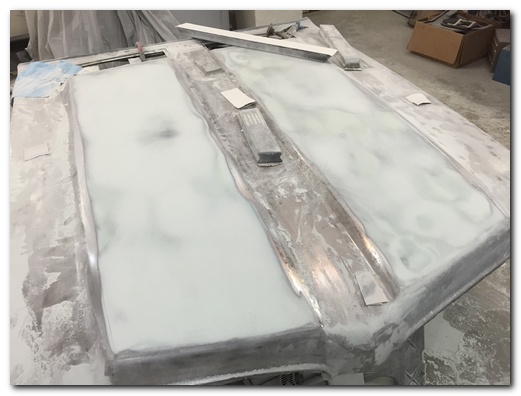

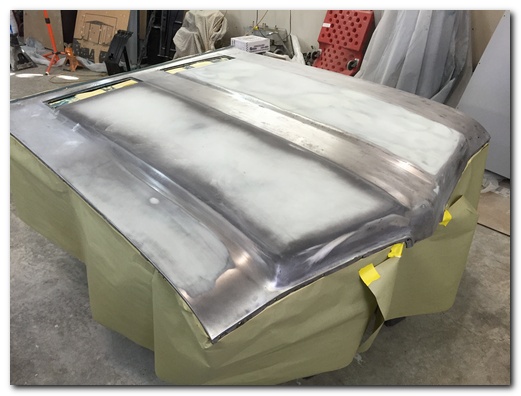

After a LOT of sanding to get the hood to bare metal I began skimming the

hood with body filler, Then I sanded with a long sanding block to

attain a smooth straight surface.

They are very large and long, I've really got to work hard to make sure they

are as perfect as possible. A flaw here would really show up after

paint.

I use really cheap flat black spray paint to dust the surface and then use

the long sanding block to show high and low areas. It's called a guide

coat and works really well to determine if there are imperfections in my

work.

I spent a lot of time and effort on this and I'm sure it will pay off.

|

|

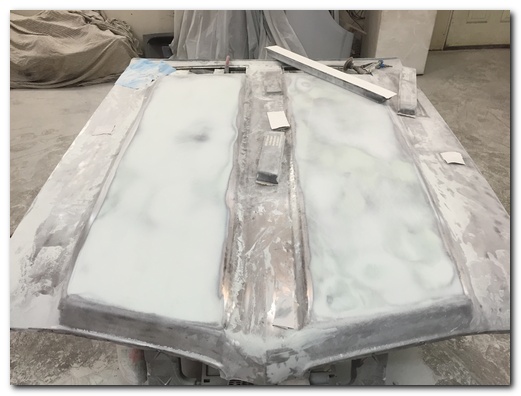

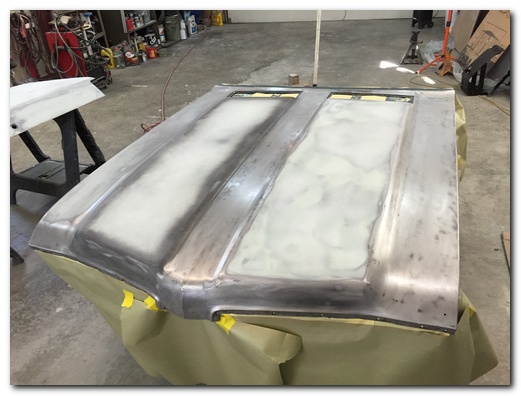

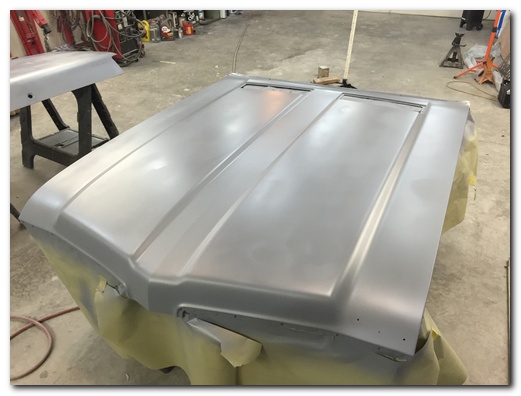

After I was satisfied with the hood I turned to the trunk deck lid.

Here the moron who painted it last showed his lack of talent and

attention to detail again.

Everything was just sprayed over and was completely the wrong color. |

Just a bunch of time with a sander and a wire wheel to get it down to bare

metal. It will be epoxy primes and then painted body color and clear

coated. I'll need to remove the paint from the latch and other parts

that shouldn't be painted.

Again just a lot of messy paint removal.

The deck lid is in remarkable condition. There was one small dent

near the lock cylinder. Other than that it is really straight and

will only need a very thin skim coat to ensure it's flat as can be. |

|

|

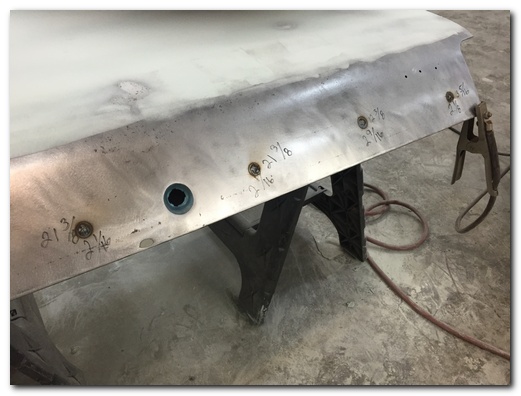

Originally there was a long molding that ran the width of the trunk lid

along the bottom (as seen below). This piece is not reproduced and it

is impossible to find one that is not completely pitted or broken. The

original one is in very poor condition.

I decided like most others to delete it. I will need to fill the

mounting holes before doing any other body work.

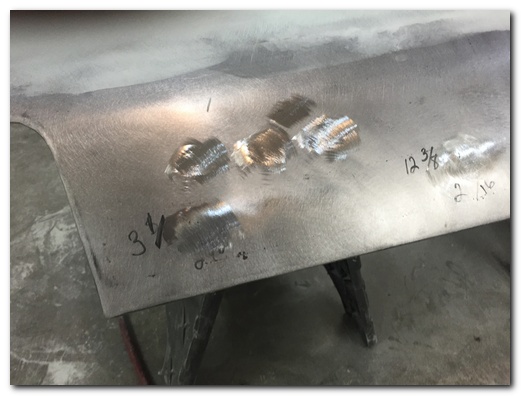

I measured the holes locations just for a matter of record.

These three holes on the drivers side of the lid were probably for a dealers

emblem. The previous "body man" had filled them with body filler.

Not the correct way to go about this.

I welded the holes up.....

as well as the holes for the long piece of trim.

This is how it should be done.

The welds are dressed with a grinding disk and are virtually invisible.

Then a thin coat of filler to ensure it's flat as can be.

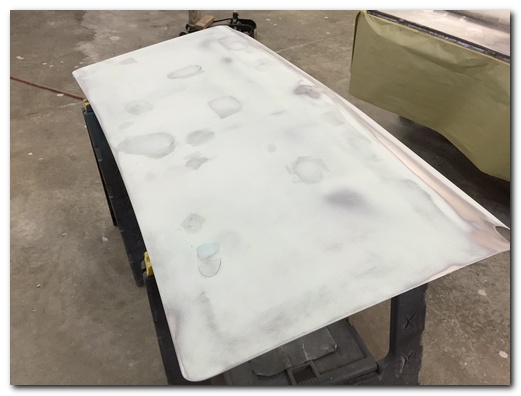

After a thorough cleaning we are ready for some epoxy primer!

Two coats of primer.

It's amazing how good these parts look when they are all one color.

Next up was four heavy coats of high build primer-surfacer just like was

done on the doors and body.

This will sit for three days before sanding.

After block sanding them with a long block and using a guide coat.

There are still some small imperfections that need to be fixed.

Another few coats of high build primer should solve our problem.

A couple shots while the last coat was still wet. It looks really

really flat and straight from the reflections!

Door and Fender Alignment

While that's drying for a few days I want to get the doors and fenders

mocked up and adjusted.

It's really great to see the doors hung again!

They haven't been on the body since the first day I brought it home.

Once the doors were finally adjusted to the body I set the front fenders in

place.

You always want to set the gaps from the rear to the front. In other

words get the door adjusted to the body and then the fender adjusted to the

door.

This took a very, very long time. A lot of small adjustments here and

there to achieve the best gaps possible.

WOW! it looks like a car again! I'm really happy how it looks.

I then document what and how many shims go where so when it goes back

together it should go right back to the exact same positions.

Time to take it all back apart again so I can paint the door jamb openings

and block out the doors and body..........

Lots more to come!

Check back often.

Back

Back

Home

Home

Next

Next